Top Mistakes to Avoid When Using PVC Foam Boards in Home Interiors

Top Mistakes to Avoid When Using PVC Foam Boards in Home Interiors

Think all foam boards are the same? Think again. PVC foam boards are gaining ground rapidly in Kerala homes for good reason: they’re moisture-resistant, termite-proof, and easy to maintain. From modular kitchens to bathroom cabinets, the material is a favorite. But apart from their advantages, incorrect usage can lead to costly do-overs and dissatisfied customers.

Let’s break down the most common mistakes people make when using PVC boards — so you can guide clients better, build trust, and avoid unnecessary product returns.

Mistake #1: Using PVC Foam Boards in High Load-Bearing Furniture

Here’s where things often go wrong: homeowners or carpenters use PVC boards for tall wall units or lengthy open shelves. They look sleek and modern, sure. But without the right support, they’re bound to sag.

Why it doesn’t work:

PVC boards are lightweight by design. That’s a plus for wall panels or shutters, but a red flag for structures that hold heavy items. Unsupported use in load-heavy cabinets, especially in kitchens, can lead to bending or breakage over time.

Kerala Tip: This is a common error in upper cabinets of modular kitchens in humid regions like Ernakulam.

What to do instead:

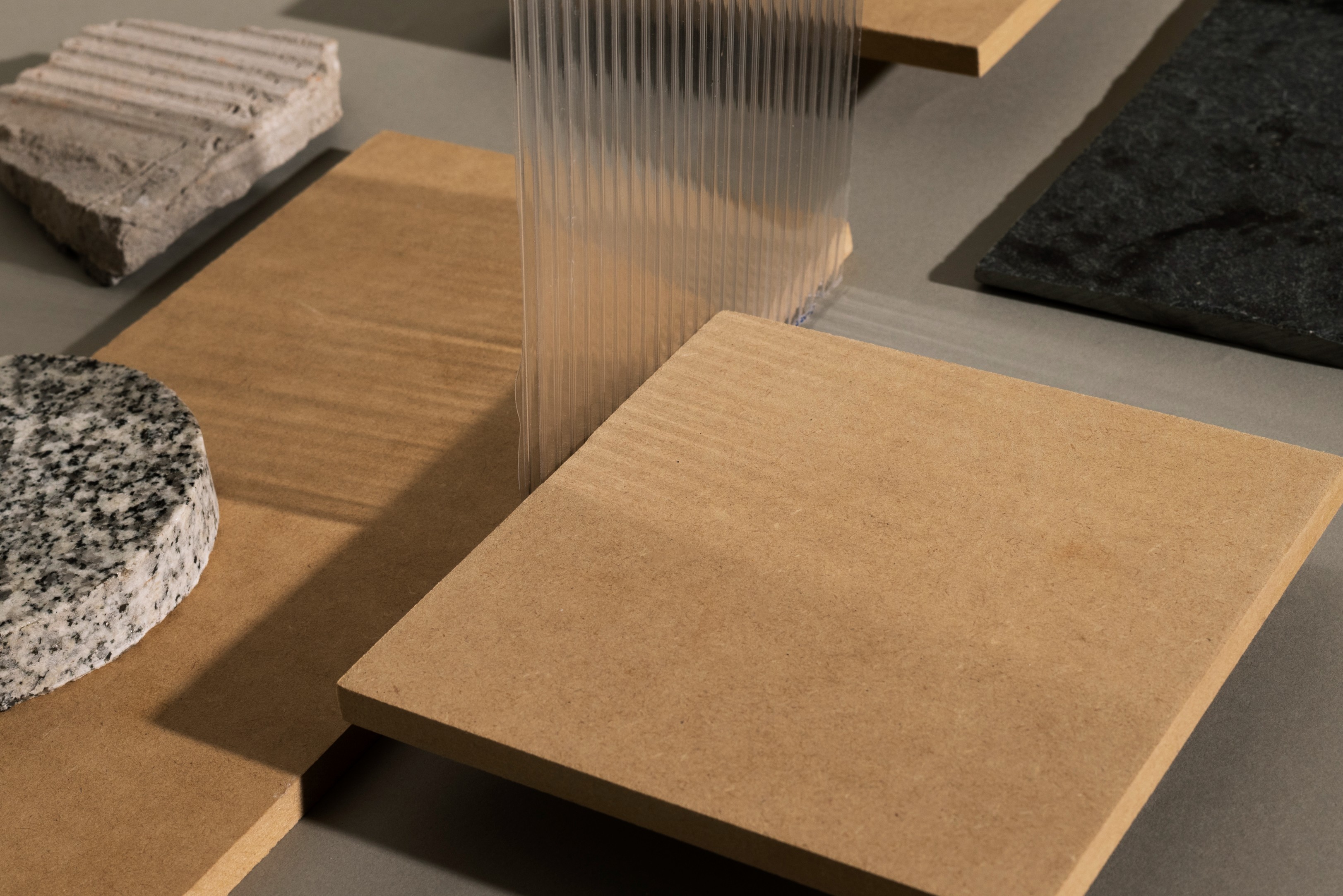

Use aluminium profiles, wooden framing, or steel reinforcements to support the board. For units holding granite or appliances, opt for stronger core materials altogether.

PVC foam board in Kerala kitchens often fails when used unsupported for heavy crockery units.

Mistake #2: Not Sealing or Laminating the Surface

A bare PVC board might seem clean and minimalistic at first glance. But leave it uncoated, and you’ll soon notice it attracting oil stains, smudges, and scratches.

Why it’s a problem:

Yes, PVC foam boards do resist water and pests. But an unfinished surface collects dust and grime easily.

Homes near coastal belts like Alappuzha often experience salt air exposure. This wears out unfinished surfaces faster.

Fix:

Laminate, UV coat, or simply paint matte or satin.

Using a foam sheet in Kerala’s humid interiors or dry regions? Always finish the surface for best results.

Mistake #3: Screws, Adhesives, or Joinery Techniques That are Improper

In a rush, many carpenters treat PVC foam like plywood — hammering in regular screws or using basic adhesives.

Here’s the catch:

PVC foam boards aren’t as dense. Rough handling or wrong tools can crack the surface, especially at edges or corners.

Common in Kerala: Quick DIY renovations or festival-time home makeovers in towns like Palakkad often overlook proper fixing methods.

What to use instead:

Go for polyurethane-based adhesives and fasteners

Specifically designed for PVC materials

Always pre-drill screw holes

Avoid overtightening.

Don’t risk product returns by using poor fixings — even the best PVC foam sheet near me can fail if not handled right.

Mistake #4: Installing PVC Boards in Flooring or Outdoor Applications

PVC boards might seem all-weather on paper, but using them as outdoor decks or flooring? That’s a no-go.

Why it’s risky:

They can warp under direct sun, swell from constant rain, or fade due to UV exposure. Their structure isn’t made to handle direct pressure over time.

Kerala Watchpoint: PVC is mistakenly used in houseboat flooring or balcony decks in places like Kumarakom — often leading to warping.

Better choice:

For such applications, recommend WPC (Wood Polymer Composite) or high-pressure laminates that are engineered for external stress.

PVC foam board in Kerala interiors should stay indoors, especially away from harsh monsoon exposure.

Mistake #5: Expecting Too Much Design Flexibility Without Support

What we have seen: Clients ask for ornate CNC carving, curved pooja units, or moulded TV panels using just PVC.

The reality:

PVC boards are great for clean lines and flat designs, but not ideal for intricate cuts or curves without cracking.

Kerala Relevance: In Thiruvananthapuram, there’s a growing trend of modern pooja units — but PVC often fails to deliver the curved elegance expected.

Solution:

Use PVC for flat panels but combine with ply or MDF for those curves. Explain that its strength lies in simplicity, not complexity.

If your client wants modern aesthetics using a foam sheet in Kerala homes, keep design expectations aligned with material capability.

Bonus Tip: Improper Storage Before Installation

Even before the installation begins, the damage can start.

What happens:

Boards are stored standing upright, near windows, or in damp garages. This causes warping or discoloration.

Kerala Reminder: High humidity levels in cities like Kollam make proper storage a must.

Storage rule:

Lay boards flat on an even surface, away from sun or moisture. Proper stacking ensures they remain in perfect shape.

Conclusion

PVC foam boards are durable, sleek, and cost-efficient — but only when used correctly. Every mistake above can turn a great product into a customer complaint.

As part of your role in sales, consultation, or support, make it your job to spot these red flags early and guide clients correctl.

Need a quick refresher on what works where? Bookmark this guide or share it with your dealer network.

Looking for quality-assured PVC foam sheet near me or across Kerala? Our updated catalogue has it all — backed by expert support and durable options.

FAQ

1.What are PVC foam boards used for in home interiors?

They're perfect for wardrobes, false ceilings, wall panels, bathroom cabinets, and kitchen shutters – especially in moisture-prone areas.

2.What is the biggest mistake when using PVC foam boards?

Using them in high-load-bearing furniture without reinforcement.

3.Are PVC foam boards suitable for load-bearing furniture?

Not on their own. They need proper frames or internal support.

4.Do PVC foam sheets need lamination or painting?

Yes, for better aesthetics and protection. Unfinished boards may look raw or stain over time.

5.Is it fine to screw or glue PVC foam boards?

Yes, but only with suitable adhesives or pre-drilled screws designed for PVC materials.

Recent Blogs

How to make Kitchen attractive?

09 Oct, 2021

Interior design materials that are the most Eco-Fr...

11 Oct, 2021

Ideas for Stunning Ceilings

11 Oct, 2021

Looking for an appropriate Gate for your House?

29 Oct, 2021

Manufacturing and Resistance of WPC Boards, PVC Sh...

29 Oct, 2021

Why most people choose PVC Walls

19 Jan, 2022

How Amazingly Facade Adorns An Architecture!

02 Mar, 2022

Advantages of WPC Boards Over Plywoods

20 Dec, 2023

Creating Stunning Outdoor Spaces with Denwud's...

08 Jan, 2024

5 Reasons Why You Should Choose PVC Foam Sheets...

10 Jan, 2024

Installing and Maintaining PVC and WPC Products

18 Jan, 2024

How to Create an Eco-Friendly Interior

29 Jan, 2024

5 Creative Ideas for Kitchen Cabinets

06 Feb, 2024

Benefits of Choosing WPC Boards | Denwudn | Kerala

14 Feb, 2024

Interior Design Ideas with Fluted Wall and Ceiling...

22 Feb, 2024

Why WPC Is The Architect’s New Favorite

11 Mar, 2024

Advantages of PVC Furniture: Stylish, Durable, and...

19 Mar, 2024

4 Reasons Why PVC Windows and Doors Are the Ultima...

27 Mar, 2024

Which is the Superior Choice? WPC Doors vs. FRP Do...

11 Apr, 2024

5 Reasons why you should use WPC doors

14 May, 2024

Choose Sustainability with WPC Board: The Future o...

30 May, 2024

Comparing WPC Boards to Traditional Wood: Pros and...

25 Jun, 2024

Choosing the Right PVC Foam Board for Your Project...

25 Jul, 2024

Transforming Interiors with PVC Foam Board: Modern...

16 Aug, 2024

Maintaining and caring for WPC boards: Tips for Lo...

28 Aug, 2024

Why WPC Boards Are the Perfect Eco-Friendly Altern...

11 Oct, 2024

Building Your Dream Interior? Here’s Why WPC and P...

29 Oct, 2024

How to Select the Proper PVC Foam Board Thickness...

07 Nov, 2024

Top Reasons to Choose Multiwood Sheets for Your Ho...

15 Nov, 2024

How to Choose the Best Multiwood Dealer for Your H...

05 Dec, 2024

Cost-Effective Solutions: How PVC Foam Boards Can...

28 Dec, 2024

The Process of Manufacturing WPC Boards: From Wast...

09 Jan, 2025

How Denwud Sheets Offer a Budget-Friendly Solution...

30 Jan, 2025

Why Choose WPC Boards for Your Home Renovation in...

14 Feb, 2025

WPC Boards for Outdoor Use: Durability and Weather...

25 Feb, 2025

Comparison of WPC Boards with Other Composite Mate...

06 Mar, 2025

Why Multiwood is the Preferred Choice for Modern H...

14 Mar, 2025

How to Choose the Best Multiwood Dealers for Your...

11 Apr, 2025

Advantages of Using Multiwood Sheets Over Plywood

25 Apr, 2025

Where to Find the Best Multiwood Sheets for Your H...

05 May, 2025

How Multiwood Dealers Are Meeting the Needs of Mod...

16 May, 2025

Local Sourcing vs Online Purchase: Where to Buy PV...

05 Jun, 2025

How to Use WPC Boards for Wardrobes and Interior F...

19 Jun, 2025

The Beginner’s Guide to Using Multiwood Sheets in...

07 Jul, 2025

Everything You Should Know About Waterproof WPC Bo...

07 Aug, 2025

WPC Board vs PVC Board: Which One Should You Choo...

28 Aug, 2025

Emerging Trends in Multiwood Products and How Deal...

12 Sep, 2025

Creative Ideas for Kids’ Room Decor Using PVC Foam...

25 Sep, 2025

PVC Foam Board vs. Plywood: The Ultimate Compariso...

08 Oct, 2025

Top Reasons to Choose WPC Bathroom Doors for India...

30 Oct, 2025

A Guide to Choosing the Right Multiwood Dealer for...

27 Nov, 2025

The Long-Term Financial Benefits of Choosing WPC B...

01 Dec, 2025

The Ultimate Guide to 3-Layer WPC Boards and Their...

23 Dec, 2025

Why You Should Choose Denwud’s 3-Layered WPC Board...

29 Dec, 2025

How to Choose the Right Decorative Laminate Sheet

22 Jan, 2026

What Are 5-Layer WPC Boards? Features, Benefits, a...

02 Feb, 2026

What Makes a 5-Layer WPC Board Different from a Re...

20 Feb, 2026